Harley Cylinder Hone

Mike RoenMike has a rigid Harley cylinder hone, a ball hone, a boring bar, honing oil, and torque plates out on the bench. Mike already has one of our Evo cylinders set up between torque plates. This is a good time to demonstrate what a machinist will be doing when you send your cylinders out to be freshened up.

It is important to follow instructions for the pistons that are being installed. Since our Heritage is getting a new set of S&S flat-top pistons, Mike has the S&S instructions on the bench for reference.

Torque plates are bolted onto the cylinder. The main job of the torque plates is not only for conveniently holding & securing the cylinder in a vise. The torque plates distort the cylinder to simulate the way the cylinder will be when torqued between the crankcase and the head.

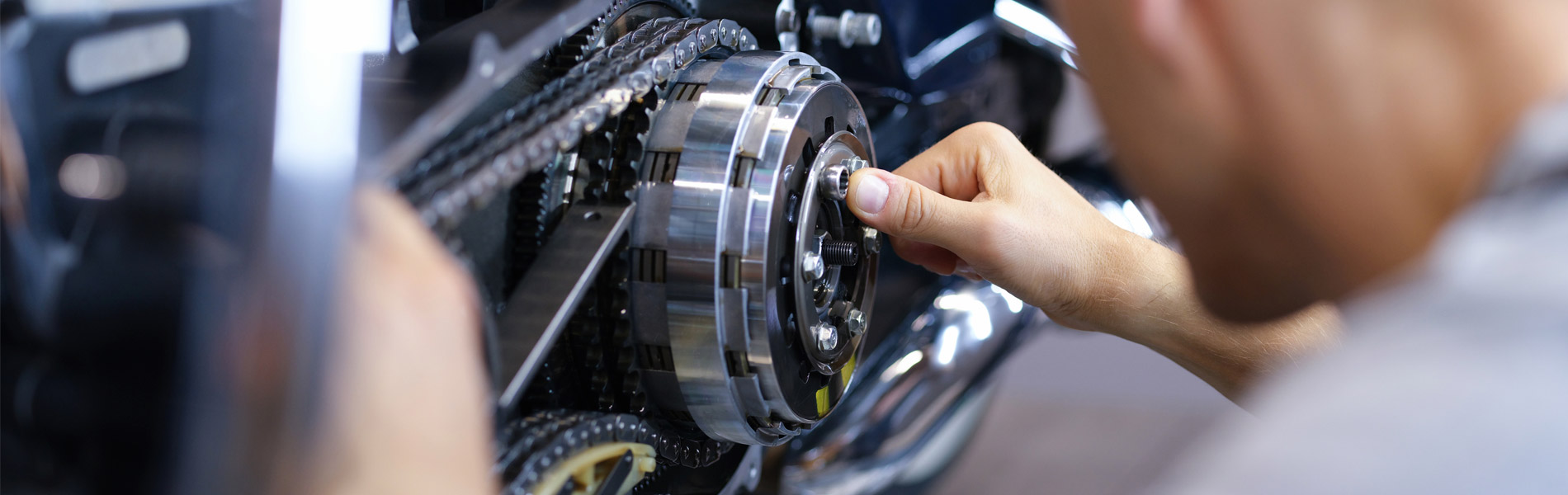

MIke lubricates the cylinder and begins lightly working the cylinder with a rigid Harley cylinder hone. The hone is moved up and down the cylinder with consistent, even strokes. Mike periodically stops to measure the cylinder bore with a boring bar. He also periodically stops in order to keep the cylinder lubricated.

The rigid Harley cylinder hone removes material while leaving a nice, uniform, 60° cross-hatch.

Mike removes the torque plates and reminds us the importance of thoroughly cleaning the base and head gasket surfaces. Once the surfaces are cleaned, they should be inspected with a straight edge. If gasket surfaces are not perfectly straight, the motor may have premature oil leaks or may blow a head gasket.

Next, Mike demonstrates how to inspect the piston ring end gap. One ring at a time is installed into the cylinder and pushed in evenly with the piston. Feeler gauges are used to measure the end gap. If the end gap is too tight, rings should be properly filed. Again, it is important to follow the correct instructions for ring end gap. Instructions will be different for different manufacturers and different motors.

Mike demonstrates how to correctly position piston rings on the pistons so that the ring end gaps are properly positioned. With one wrist pin circlip installed on each piston, Mike is now ready to install the new pistons onto the connecting rods.