Panhead Brake Maintenance

Kevin BaasIn this video, Kevin gives us a close overview of the Panhead brake system. Specifically, at the front and rear Panhead brake and brake drum assemblies.

When performing routine maintenance or service on a Panhead, it is always important to look for possible worn, missing, or loose parts and hardware. The front and rear Panhead brake drums are secured to the star hub style rims with tapered lug nuts. If these lug nuts become loose, braking function will be adversely affected.

These older braking systems do not offer significant stopping power, even when operating at 100%. If anything compromises or lessens the braking systems, it can be extremely dangerous. If lug nuts are to loosen or wear on the rear wheel, braking will be compromised as well as the secondary drive because the rear sprocket and brake drum are one unit.

Kevin gives us a close up of the 18", rear, star hub wheel and Panhead brake drum assembly on the bench. The drum has locating pins for proper positioning and indexing on the start hub. When assembled correctly, the holes will be aligned so that a 7/16" allen can reach through for turning the lug nuts. When assembling a drum onto the hub, it is important to have all surface areas thoroughly clean. The lug nuts should also be thoroughly cleaned. If lug nuts are rusty, they should be cleaned with a wire wheel. Apply a small amount of red Loctite onto the lug nuts and tighten in a cross pattern. Final torque should be 66 to 80 foot pounds.

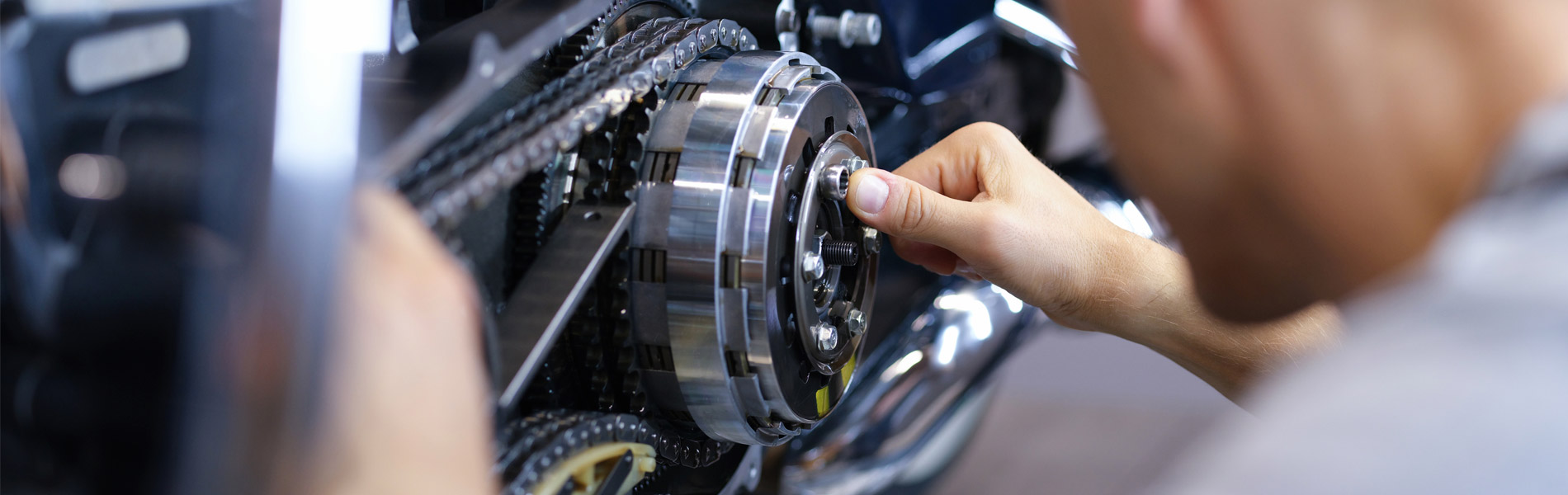

The drum Panhead brake backing plate assembly includes two brake shoes, a spring and a cam. The rear most brake lever moves the cam to force the brake shoes apart or outward from each other. The spring helps the shoes to return back to their resting position. The backing plate should be clean and free of excessive rust, grease, or debris. If the spring is mis-shaped or worn, it should be replaced.

Apply a very light amount of grease to moving and pivot points. There should not be excess grease that can find its way to the brake pads or drum surface. Inspect the Panhead brake drum lug nuts at every service.

Inspect the brake shoes and backing plate assembly every time a wheel is removed.