Primary Fluid

Kevin BaasPrimary chaincase fluid change is an important procedure to be performed at regular service intervals. Kevin Baas gives us inspection and procedure tips while he services the primary drive on an early Twin Cam Ultra Classic.

Hey, Kevin Bass here, Vintage Bike Addiction. I'm here, we're going to fix my hog. We're doing a little maintenance on this, uh, uh, Ultra Classic. And, uh, we went through Dennis Kirk and got some supplies. I'm gonna show you how to do the primary chain lubrication.

OK. So again, with any bike you work on, you always want to check the factory manual. It will tell you specifications, how much fluid is needed and when it should be changed. Um, most of the stuff on these bikes is about the first 1000 miles, and then every 5000 miles after that. Um, if you ride a lot and you ride hard, you'd like to check them a little sooner than the 5000 mile mark.

But if you're just doing easy riding on it, you're not putting a lot of, a lot of miles on every year. 5000 miles should be good. 5000 miles should be good. This bike, uh, we checked it about 5000 miles ago, so we're right on spec now to, to give it a look. First thing you want to do, um, clean off your engine.

We removed our spark plugs because we're gonna have to roll it through and check our chain. We removed our spark plugs because we're gonna have to roll it through and check our chain. We have two inspection covers that are gonna come off. Both of these run off a T27 torque bit. So make sure you have the correct torque bit.

You don't want to strip out those, uh, bolts in there. So, I loosened everything up. The last T27 torque bits can come out. The inspection cover can come off. We'll set that aside.

Now, in here, what you're gonna see is your primary chain and your primary chain adjuster pad there. Now, what you want to do is as you drive these bikes and as you accumulate miles and time goes by, these chains do stretch, OK? So you'll start to see, you'll have a, a loose spot in it and a real tight spot. Most of the time, so what we wanted to do and what we did is we removed our spark plugs so we could put it in gear, roll our rear tire, watch this chain go, and I felt it until we got to our tightest spot, OK? You always want to adjust these on the tight spot, not the loose, sloppier spot.

So I found our tightest one, and this one was pretty good. It was pretty consistent all the way around, so it's not too bad. Um, and then this cover here, inspection covers is what we're gonna take off when we add our fluid, and, uh, I'll show you that shortly. So, again, with this, the primary chain, because we're gonna change the fluid, it's a good time to check your chain. There is an adjuster pad in there.

That wears out, so you want to make sure that your, your pad that's in there, the primary chain adjuster pad, isn't all worn through or grooved out a lot and slotted real bad from the wear and tear. This one looks good, so I'm not going to replace it, but had I need to, this is what they look like. There's just a clip in there. You can pop the clip off. Um, obviously, you'll have to take the cover off to get that to slide all the way out, put the new one on, put the clip back on.

But that's what that would look like. The one in there right now still looks almost like new, so no need to replace it, but these are what they look like. Uh, so now I know that's good. We rolled our bike and we checked to our tight spot. I'll use my steel rule.

Just get down and we want cold. This is cold now. It is 5/8 to 7/8 of an inch. So just under an inch is still within spec. When it's cold.

If this would be hot, it would be 3/8 to 5/8. I do not recommend checking this so when it's hot. You don't want to get burnt, hot motor and everything else. Do it when it's cold. It's a lot easier.

It's less wear and tear in your body. But I'm gonna look up in there. I'm gonna put the ruler behind the chain here. Up next to it, and then I'm gonna wiggle it up and down. To make sure I'm within that spec.

And I am, I'm at about. Uh, about 5/8 of an inch. So I'm right at the tolerance there, uh, of the low end, which is good. So it's 5/8 to 7/8 inch, so I'm good. After 7/8 of an inch, that means it's going to be too sloppy.

So 5/8 is good. I'm happy with that. I don't have to change that. I don't have to adjust it. If I was in need to adjust this, all you have to do is there's a locknut right in here.

We would loosen that lock nut, and then I can carefully move it because there are little teeth on that, there's little teeth on that, and you can just move it up tooth by tooth, then double check, crank it back down, and double check until you get the correct tension again. Once you get to the point, though, when these chains get to be so worn out that even on your tightest spot, you can't get it tight enough, it's going way up and it's still sloppy, then replace your chain. This one's all within spec. Everything feels good, everything looks good, so we're not going to worry about doing anything with the chain tension or, uh, replacement. We're good to go.

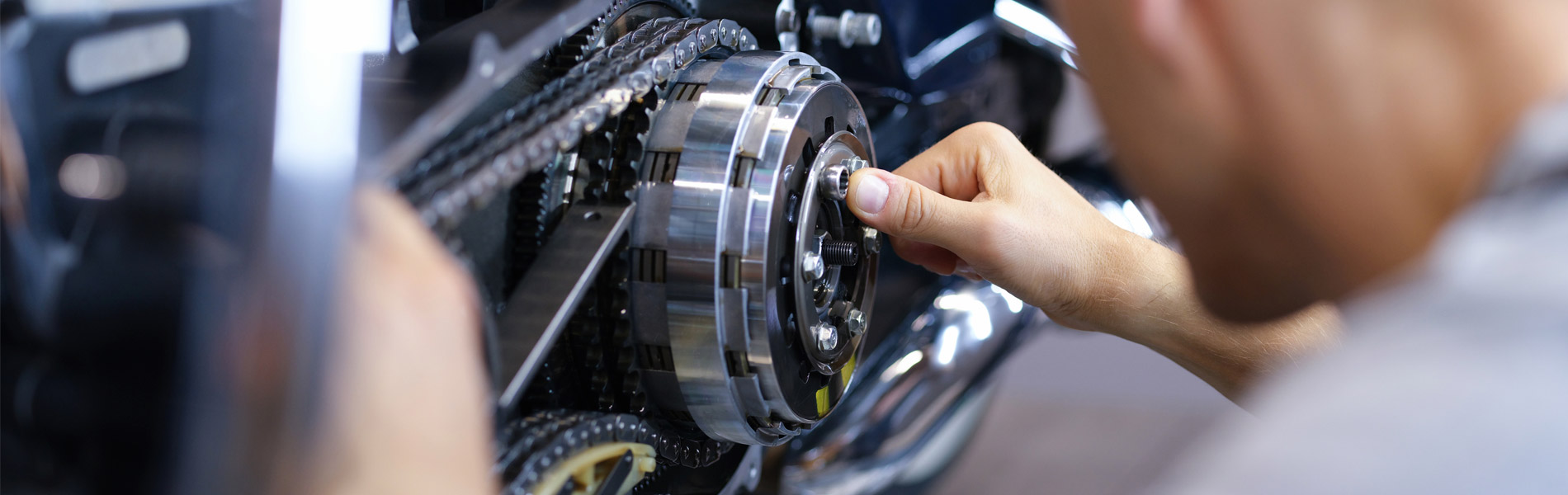

So now we can move on to our primary fluid and our lubricant. So when we take our inspection cover for our clutch off, we're going to be filling up our primary fluid. Um, and again, we can do it through either of these windows. It's actually probably a little easier to do it in the primary chain, uh, adjustment window, because you've got a bigger area to pour it in instead of trying to pour it down the side here. But we want to just open this up and take a look at it and just do a visual of your clutch plates, make sure you don't see any, if you see any metal shards or any kind of ground material that could be cause of your clutch plates wearing out or anything wrong that might be going on.

If stuff wears out, you want to replace that or take it apart. Again, this looks good. Everything is nice and clean. There's no grit to it, so I'm happy with that. So at this point, then, um, all we need to worry about, this is our drain plug down below, OK?

We're going to release our drain plug. We'll have a catch bucket here for the oil to flow into. Once we're all the way drained out, uh, we will put that back in, and then this does call for, um, 32 ounces of primary fluid. And what's nice about these is they have a set number for you, so you don't have to worry about filling it to a certain line or an overflow. All you gotta do is measure out your 32 ounces, dump it in, and it's good to go.

So, I'm going to get a bucket under this. We'll get this fluid drained, and I'll show you how to replace it. Make sure you've got your bucket under it, and there comes our fluid. Now you can see this fluid is pretty dark in color. It was definitely time to change it.

There's also a magnetic end on our drain plug. So there, you can see there's a little bit of uh debris on there, which is good that it caught it. So I'll clean that off real well. There is an old ring on here. It is advised, and the manufacturer manual does say to replace that.

Don't try to reuse it because they do get old and brittle, and they wear out. So you do want to put a new oil ring on there before you reinstall it once you've drained your old oil and added your new oil to make sure it's not going to leak. So we're gonna give this a few minutes to finish draining all the way up, and then we'll replace all this and put our fluid in. We'll be right back. All right, now that we've got our primary fluid all drained out, you can see it's just dripping the last little remnants.

Um, we went through Dennis Kirk, got our, uh, Spectro heavy duty primary chain case oil which is recommended for these bikes. If you're not gonna use the factory Harley type, again, we love Spectro. We use it in all of our motorcycles, uh, also. Remember, now we took out the drain plug, so we replaced that little O-ring, and again, we got that through Dennis Kirk, fresh O-ring on there, and I can even feel taking this old one off. It's really kind of scratchy and a little bit almost dry rot feeling, like it was gonna tear.

So it is very, very, very much recommended each time put a fresh O-ring on it. Don't try to reuse it. So, now that we have our chain case oil all drained, I'll just clean this out real quick. Remember, for this one, it's a 3/16 Allen head, so I'll put that on the end of my wrench. Carefully feed that in.

And when you put these back in, make sure you're going straight, make sure there's no garbage in there. You don't wanna, uh, cross thread these or have any garbage in the threads that could cause it. To score and scar that, which will make it leak. So, you should feel it going in nice and smooth and easy. If you feel any resistance, stop, back it out and clean that out and make sure there's nothing in those threads.

This one feels good. Gonna make it just lightly snug, not too tight. Wipe that down, look good. Now, again, it calls for 32 ounces or 1 quart of primary chain case oil. And we are again gonna use this Spectro heavy duty.

Open this up. Be careful not to let any of this foil get in your oil. And then we will. Start adding it in. And again, it's a full 32 ounces or full quart of oil to fill this properly.

Nice looking fluid there. All right. We got 32 ounces in, or a quart. Wipe down the bottom area where a little oil might have weeped. You should also check your gaskets on these if need be.

Replace them. These ones didn’t get pulled off or squirted, so I'm gonna reuse those. Those should be fine. We’re gonna go back in now and install our cover. Again, remember these are Torx, 27 Torx.

So I'll switch my Allen head now to the Torx bit. Five of them on here. And whenever you install and you tighten, bolts on covers like this, you want to do kind of a star crisscross pattern. So you get good even clamping of the surface area. You don't want to clamp one side and work your way around, or it could cause a little distortion or warpage there.

So you want to pull everything in tight and even. Together. So I'm gonna get that in just so it feels snug, go to the opposite one. Just till it starts to feel snug, opposite one here. Now I'll go back one more time and just give it a little bit more of a good little wrench to it.

Make sure I feel it seating on those lock washers. Again, you don't want to over tighten them. You don't want to strip out any threads, just make it snug where you feel the lock washer engaged but not over tight. There we go. That one's good.

Then we can go to our primary chain inspection cover. This one here again, there's a rubber O-ring around that looks good, or I'm sorry, not an O-ring on this, but a gasket on this one. That gasket is still in good shape. Let's make sure there's no debris on it. Wipe it down so it's clean.

You don't want any grit in there or grime that could cause it to leak. Push that back in. And then we have four of these. Same thing, we'll go in there and get it lightly snug. Crisscross down.

Opposite. And then we'll just give it one nice little. Pull there, feel it, locking in good. Mm. And there we are.

We'll get our spark plugs back in, plugs on. This bike, we can lower it down, uh, and we're ready to ride. So again, uh, make sure you always check your service manual, always, even when it's a new bike, first 1,000 miles, every 5,000 after that. If you do a lot of extensive riding or hard riding, check it sooner than that. And remember Dennis Kirk.com, they have all your needs between fluids, gaskets, parts and pieces for these bikes.

They ship today. So check out DennisKirk.com, order up everything you need to service your bike, and they'll get it out to you ASAP. So here's a, a safe ride and miles and smiles.

Share tips, start a discussion or ask other students a question. If you have a question for an expert, please click here.

Already a member?

No Responses to “Primary Fluid”